House in Chatham

residence on Brownings Hill Road

summary

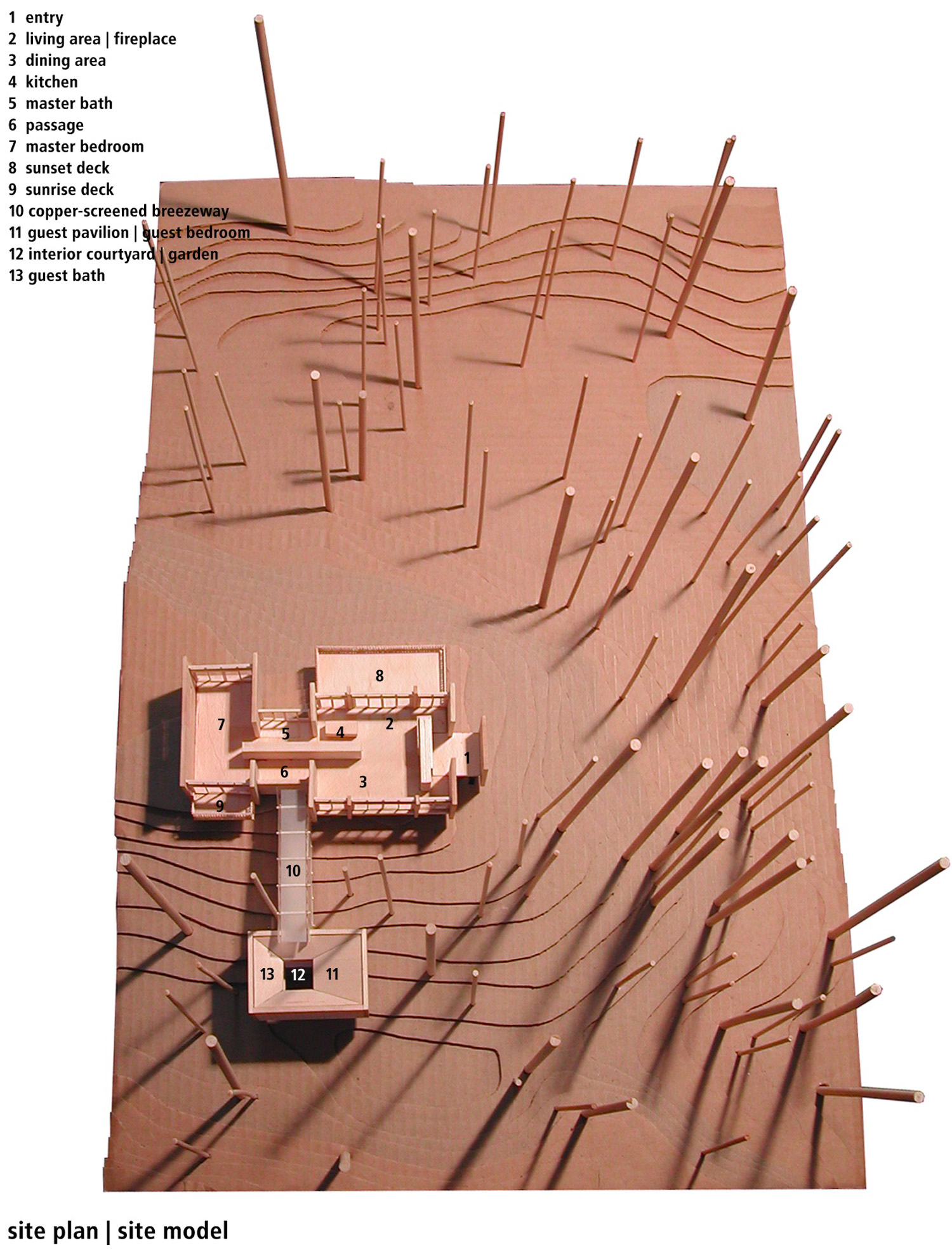

Shortly after purchasing this sloping, densely wooded 33 acre parcel in upstate New York, the inspiration from our client was that they wanted “a house in the trees.” The property has panoramic views to the West (down hill) and is surrounded by a variety of Hemlock, Oak, Pine and Maple trees.

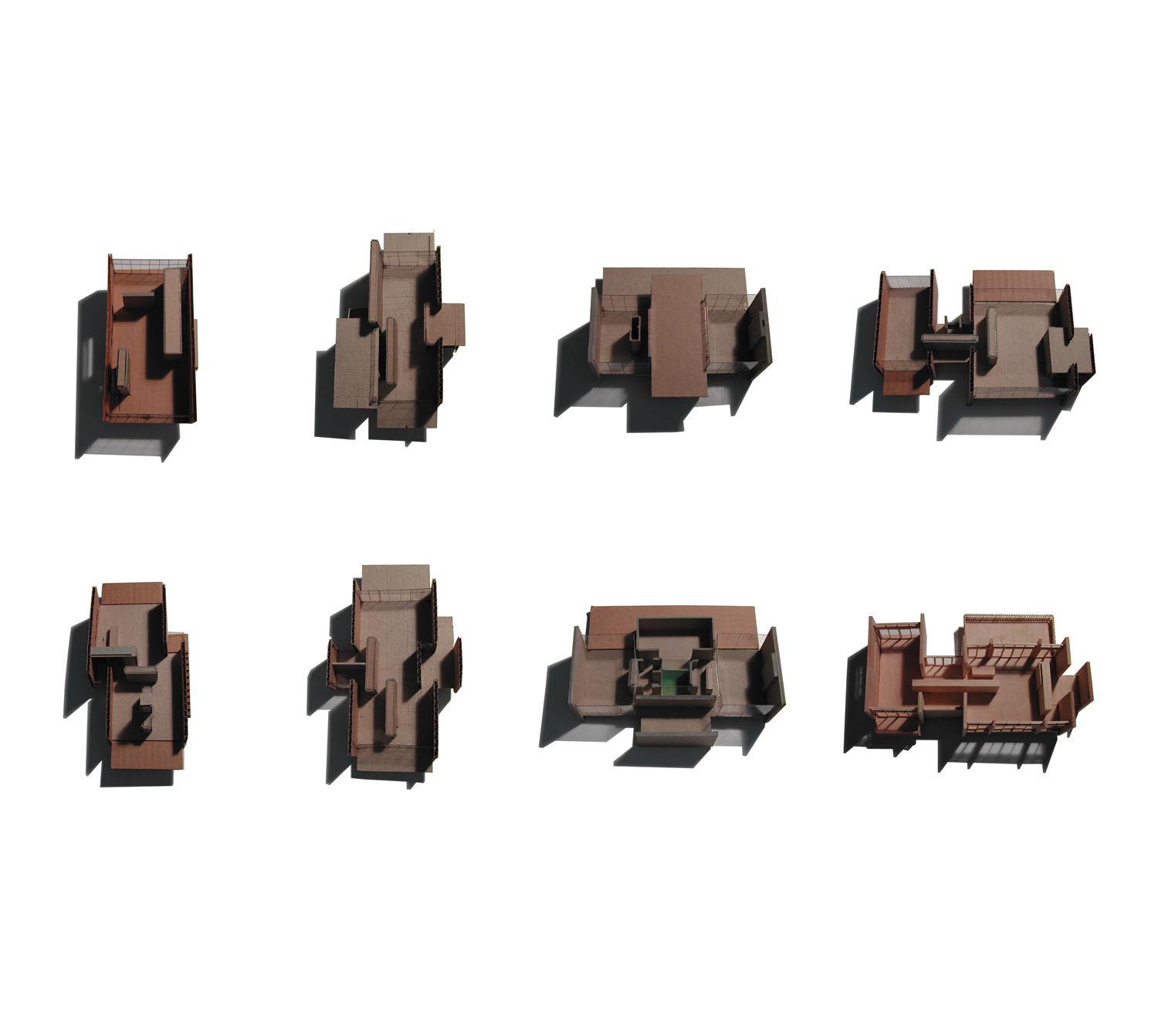

The house is a ruthlessly simple 1,200 square foot one-bedroom weekend home with a semi-detached guest pavilion and carport. The client is an urban couple with adult children, a relatively flexible construction schedule but a very limited construction budget. Because of the limited budget, we chose to employ a variety of prefabricated and modular building systems for the house. Because of our client’s love of the forest and the views to the west, we chose to design the house so that its presence on the property would be as subtle as possible. The house is sited on a ridge approximately halfway up the hillside. Its primary orientation is to the Western view, but the house also opens up to the East with views uphill to the surrounding forest.

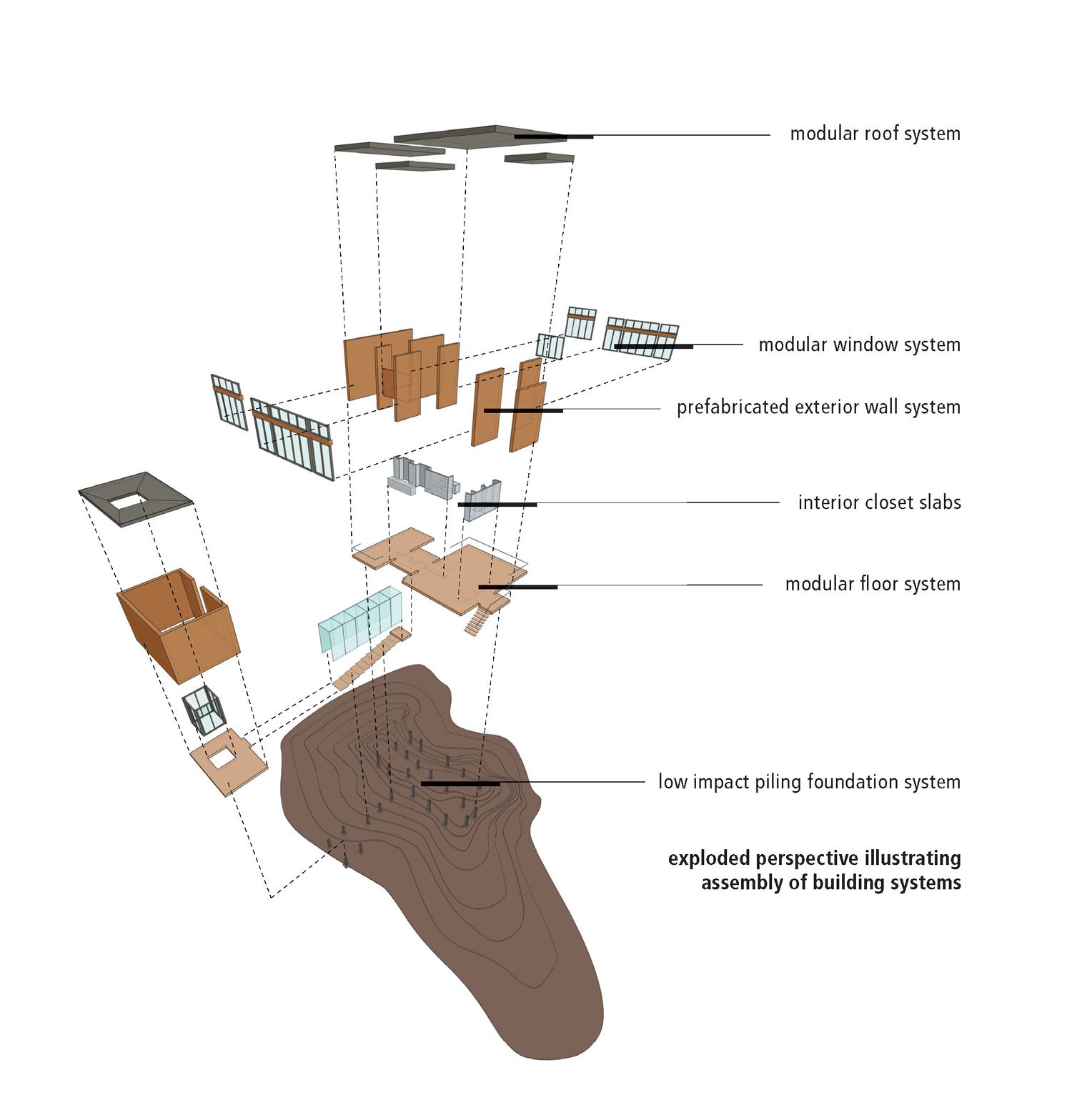

Exterior walls are prefabricated modular structurally insulated tongue and groove wall panels consisting of 10” thick rigid insulation sandwiched between two layers of 1/2” thick oriented strandboard. The exterior of the structurally insulated wall panels is clad in a corrugated copper siding oriented vertically so that the corrugations mirror the vertical repetition of the surrounding tree trunks. The copper is to be left unprotected to patina to a naturally mottled, orange-red-brown, “dirty penny” finish which will blend into the surrounding forest floor and tree trunks.

The window walls are composed of stock sliding door components. The system is glazed in energy-efficient, thermally insulated “heat-mirror” glass. “Closet slabs” define the interior spaces of the house. The closet slabs are 2’-6” deep and built on site. The undulating plaster walls house programmatic necessities required according to their location in the house. The flat roof and flooring systems are composed of modular factory-cut light-gauge metal framing; assembled, insulated and sheathed on site.

To minimize the house’s impact on the site and to economize foundation costs, the house is supported by pilings composed of 12” square concrete-filled CMU on concrete footings. By lifting the house off the forest floor, the foundation system accentuates the client’s desire for a “house in the trees.”